- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Hotline 19928718048

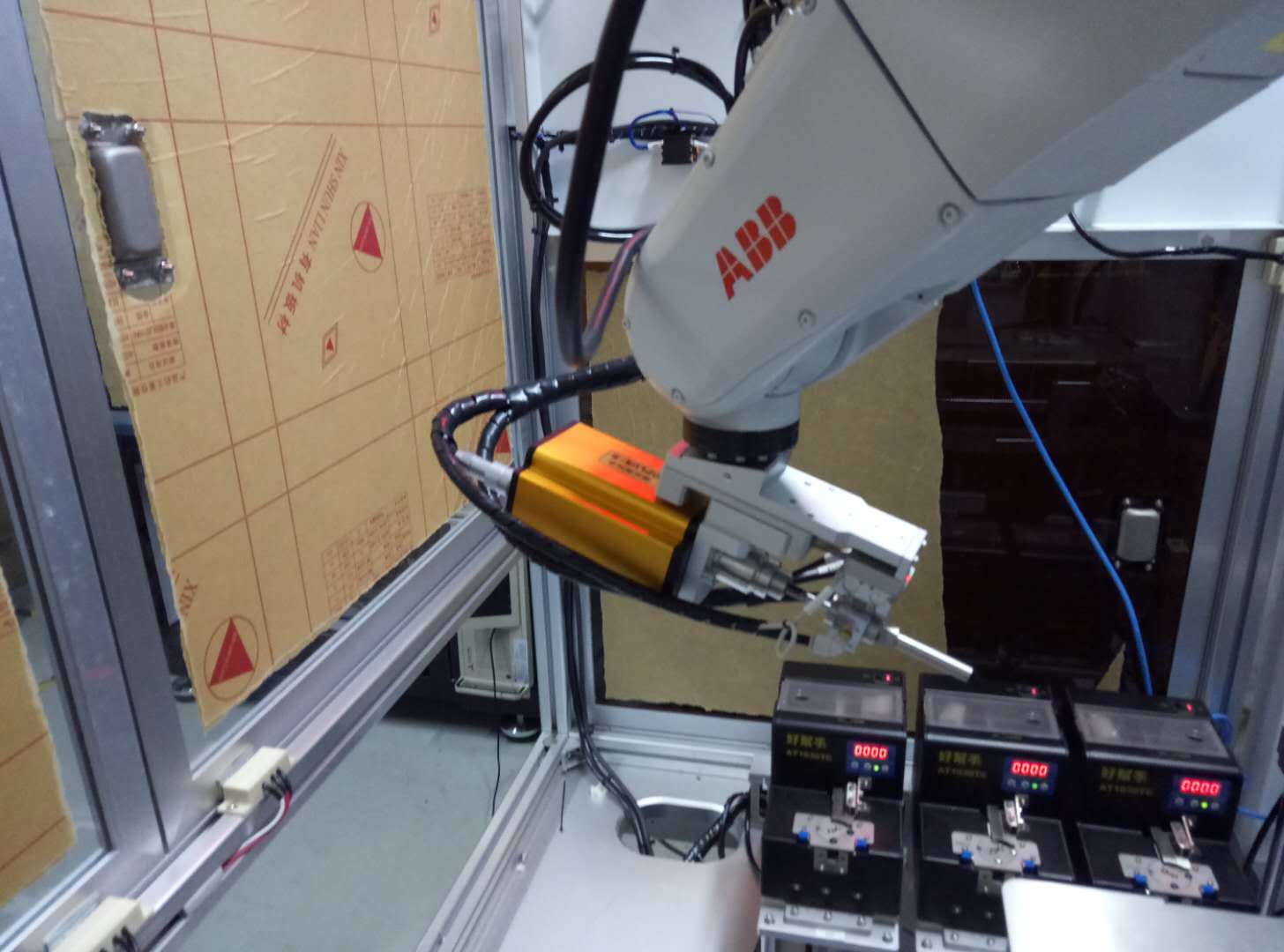

The smart screwdriver, paired with a multi-joint robot, achieves multi-directional tightening.

Classification:

Industry News

Author:

Source:

Release time:

2019-01-23

Visits:

1

Introduction: The multi-joint robot, also known as a "multi-degree-of-freedom robot," is a type of robot widely used in large-scale industrial production. Its basic structure consists of a spatial multi-link open-chain structure made up of multiple rotating joints. It has multiple degrees of freedom, with each degree being a rotating joint, and features an open structure that interacts well with the external environment. It is suitable for various mechanical automation tasks in many industrial fields, such as automatic assembly, painting, handling, welding, and more.

The multi-joint robot is composed of body parts, arm parts, wrist, and hand parts. The vast majority of multi-joint robots are based on a rotary base type body part, which serves to directly connect, support, and drive the main motion mechanism of the robot.

Multi-joint robots are typically used in the production lines of automobiles or other large equipment, requiring a set of robotic devices with a relatively large range of motion that can efficiently carry out production. This is also the reason why six-joint robots usually use a rotary base type body.

Therefore, the most prominent feature of multi-joint robots is that they differ from other planar robots; multi-joint robots can work at multiple angles. In situations like automobile assembly, screws in different locations need to be tightened at different angles, so horizontal assembly alone is far from sufficient.

When paired with an intelligent screwdriver, multi-joint robots can achieve precise screw tightening operations from multiple angles, eliminating the need for manual handling of the screwdriver. By simply setting the torque size, the multi-joint intelligent tightening device can automatically tighten screws at every angle with precision and standards, and it comes with a feedback function that allows inspectors to check the tightening status at any time. In case of emergencies, it will also sound an alarm and immediately stop working, providing an excellent tightening solution for many situations that require multi-directional tightening.

Key words:

Previous article