- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Hotline 19928718048

Intelligent Electric Screwdriver Tightening Shaft

Product Features: 1. The product has a slender body design, maximizing the use of space while being neat and aesthetically pleasing. 2. Mechanical floating lock design, with a minimum detection of 0.5mm. 3. Anti-collision detection function, effectively sensing foreign objects in the tightening area, timely preventing the Z-axis from advancing, effectively protecting the product and the tightening shaft from damage. 4. The suction nozzle does not contact the product, effectively protecting the product's surface. The screwdriver is independently advanced by the Z-axis electric cylinder, with spring free compression force to tighten the screw. 5. Programmable CNC electric tightening shaft, capable of multi-segment speed control, suitable for complex tightening processes. 6. Screw tightening always requires a stroke compensation. Therefore, all Sensewee automatic tightening screwdrivers are equipped with axial guide rails and springs to adjust the axial pressure during each tightening seating process. We do not need to use custom heads and sleeves with built-in spring guidance. International standard batch nozzles and suction nozzles are compatible.

Classification:

Products

Product peripherals

Product number:

1342542105586323456

Product Description

1. High precision torque control, torque accuracy reaches ±3%—±5%;

2. Uses high-end imported motors, long product life, maintenance-free;

3. Accurate floating height/tooth detection, feedback to PLC or control card for exception handling;

4. Precise tooth entry detection function, ensuring accurate activation of tightening signals;

5. Locking results are traceable, exportable, and can be uploaded to the MES system;

6. 16 types of tightening tasks, each task supports 5 tightening steps, disassembly tasks support 2 disassembly steps,Ensure high controllability of tightening and disassembly processes;

7. Supports RS232/485 Modbus RTU communication protocol, strong expandability, supports multiple IO input/output,

Can be customized for non-standard TCP/IP network ports, can quickly build an intelligent locking system;

8. Simple installation, easy debugging, provides interfaces and technical support for secondary development;

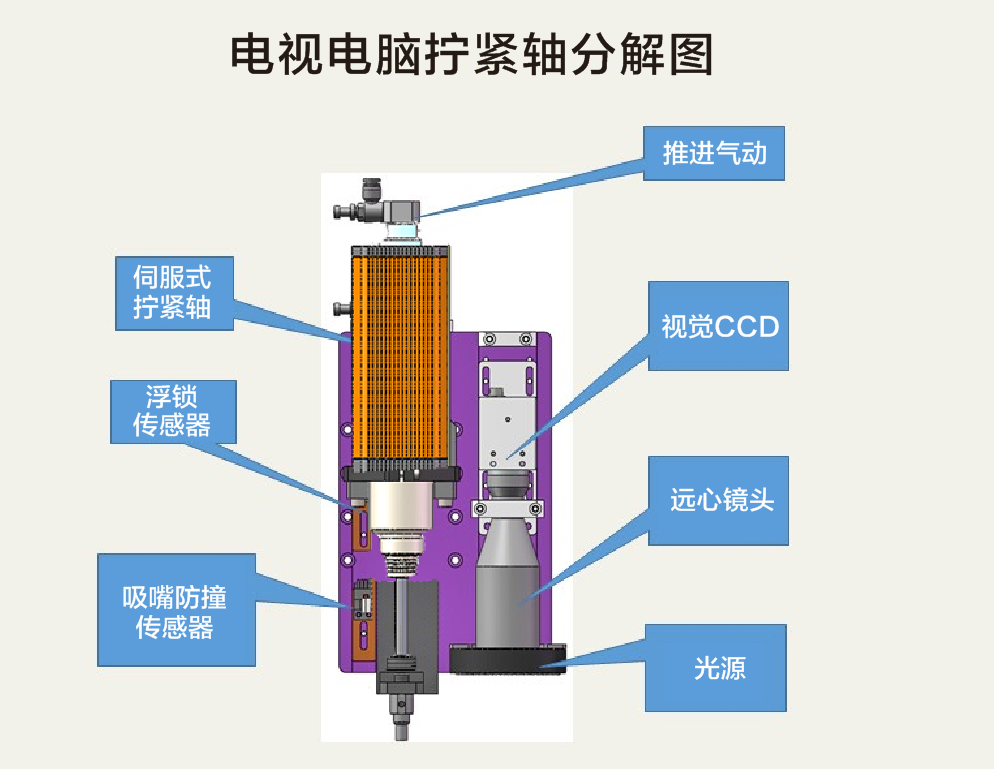

Television computer tightening shaft device

Product features:

1. Product appearance with a slender body design, neat and beautiful, maximizing the use of travel.

2. Mechanical floating lock design, minimum detection of 0.5mm.

3. Anti-collision detection function, can effectively sense foreign objects in the tightening area, timely prevent the Z-axis from advancing, effectively protecting the product and tightening shaft from damage.

4. The suction nozzle does not contact the product, effectively protecting the product surface. The screwdriver is independently advanced by the Z-axis electric cylinder, with spring free compression force to advance the screwdriver tightening.

5. Programmable CNC electric tightening shaft, can control speed in multiple segments, suitable for complex tightening processes.

6. Screw tightening always requires a stroke compensation. Therefore, all automatic tightening screwdrivers from Sensewee are equipped with axial guide rails and springs to adjust the axial pressure during each tightening seating process. We do not need to use customized heads and sleeves with built-in spring guidance. International standard batch nozzles and suction nozzles are compatible.

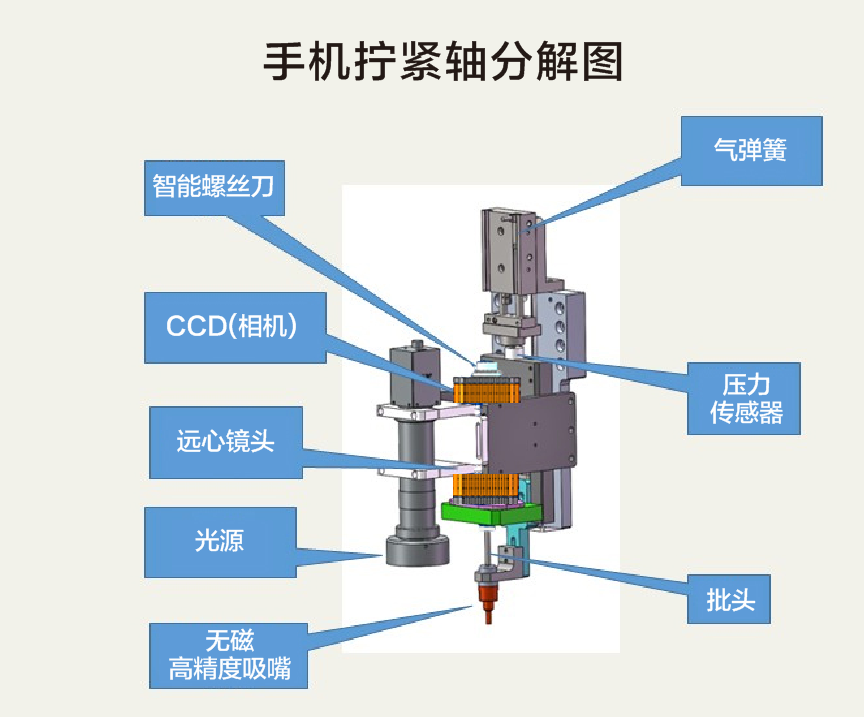

Mobile tightening shaft device

Product features:

1. Product appearance with a slender body design, neat and beautiful, maximizing the use of travel.

2. Mechanical floating lock design, minimum detection of 0.2mm.

3. Anti-collision detection function, can effectively sense foreign objects in the tightening area, timely prevent the Z-axis from advancing, effectively protecting the product and tightening shaft from damage.

4. The suction nozzle does not contact the product, effectively protecting the product surface. The screwdriver is independently advanced by the Z-axis electric cylinder, with spring free compression force to advance the screwdriver tightening.

5. Programmable CNC electric screwdriver, can control speed in multiple segments, suitable for complex tightening processes.

6. Screw tightening always requires a stroke compensation. Therefore, all automatic tightening screwdrivers from Sensewee are equipped with axial guide rails and springs to adjust the axial pressure during each tightening seating process. We do not need to use customized heads and sleeves with built-in spring guidance. International standard batch nozzles and suction nozzles are compatible.

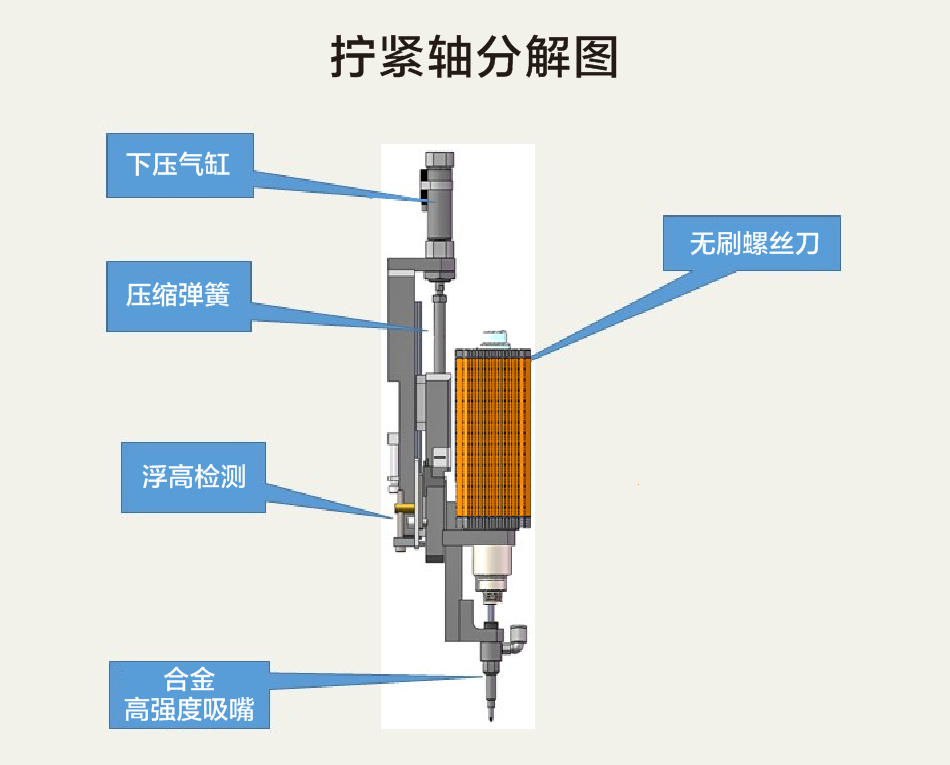

Intelligent electric screwdriver tightening shaft device

Product features:

1. Product appearance with a slender body design, neat and beautiful, maximizing the use of travel.

2. Mechanical floating lock design, minimum detection of 0.2mm.

3. Anti-collision detection function, can effectively sense foreign objects in the tightening area, timely prevent the Z-axis from advancing, effectively protecting the product and tightening shaft from damage.

4. The suction nozzle does not contact the product, effectively protecting the product surface. The screwdriver is independently advanced by the Z-axis electric cylinder, with spring free compression force to advance the screwdriver tightening.

5. Programmable CNC electric screwdriver, can control speed in multiple segments, suitable for complex tightening processes.

6. Screw tightening always requires a stroke compensation. Therefore, all automatic tightening screwdrivers are equipped with axial guide rails and springs to adjust the axial pressure during each tightening seating process. We do not need to use customized heads and sleeves with built-in spring guidance, international standard batch nozzles and suction nozzles are compatible.

Blow feed tightening shaft

Suction type tightening shaft

Key words:

Previous Page

Next Page

Previous Page

Next Page