All

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Hotline 19928718048

All categories

Smart Electric Screwdriver Locking Screw Parts Assembly Process

Classification:

Blog

Frequently Asked Questions

Author:

Source:

Release time:

2019-04-18

Visits:

1

1. Assembly:

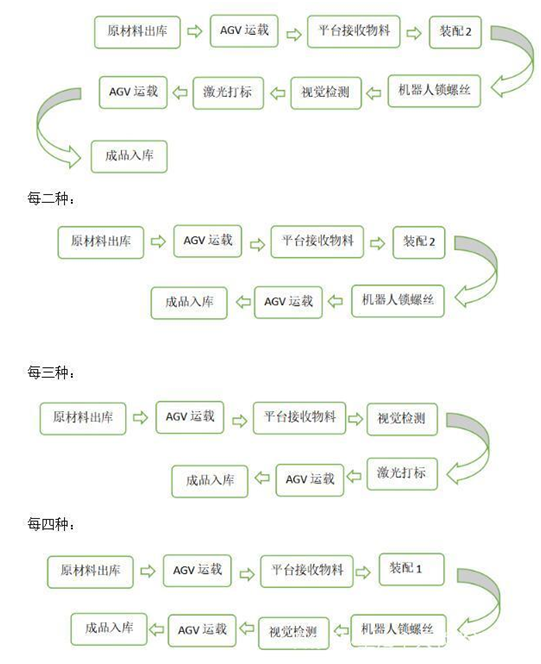

A total of 4 types of parts, 2 assembly methods, and 4 demonstration process flows.

2. Screws:

2 sizes, 2 lengths, a total of 4 combinations.

M3X6, M3X12, M4X6, M4X12

3. Inspection:

Check size, count screws, color;

4. Coding:

Different number segments are coded according to the RFID type.

Brief description of the process flow

1. Processing order generation, system placing orders;

2. The warehouse performs raw material outbound;

3. The AGV cart transports the workpieces to the corresponding workstation temporary storage platform according to the RFID process path information;

4. Industrial robots are allocated and scheduled according to MES software, placing the required workpieces at the assembly workstation and screw locking workstation respectively;

5. The assembly workstation uses robots to load and unload the flange base and flange, shape them, and then assemble them together;

6. The AGV transports the assembled components to the screw locking workstation, where the robot automatically takes screws for locking;

7. The AGV conducts visual inspection of the completed screw-locked workpiece components and performs laser marking before final storage.

Key words:

Intelligent Electric Screwdriver