- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Hotline 19928718048

Application of Intelligent Electric Screwdriver in New Energy Battery PACK Assembly

Classification:

Company News

Blog

Author:

Source:

Release time:

2022-07-21

Visits:

1

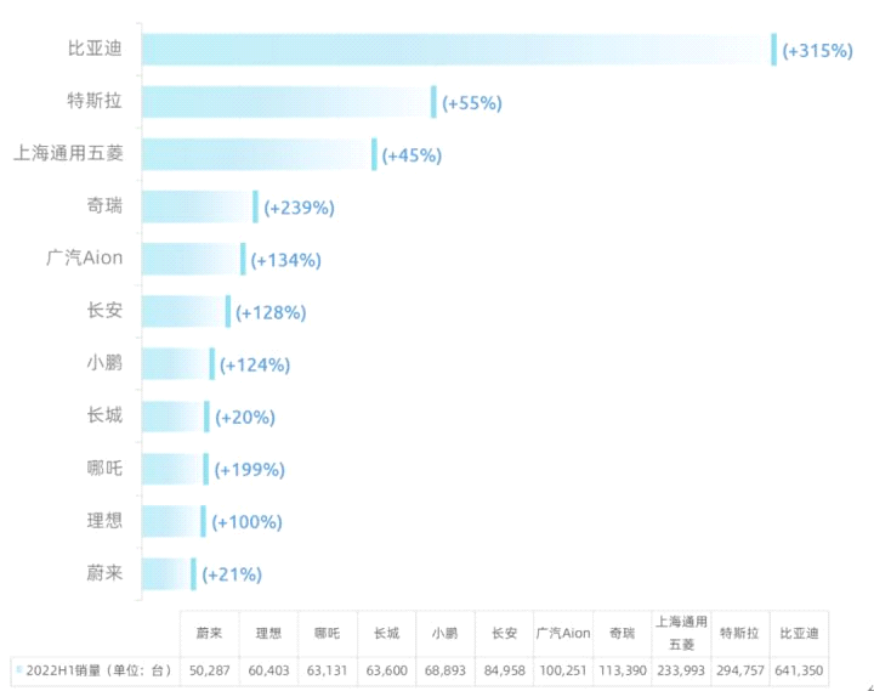

By the middle of 2022, after experiencing work stoppages and offline sales interruptions due to repeated pandemic outbreaks, global inflation, and the surge in crude oil prices caused by the Russia-Ukraine conflict, China's new energy vehicle market has seen explosive growth. It is reported that in the first half of 2022, the retail sales of China's new energy vehicle market reached 2.6 million, a year-on-year increase of 120%, especially with BYD's growth reaching 315%.

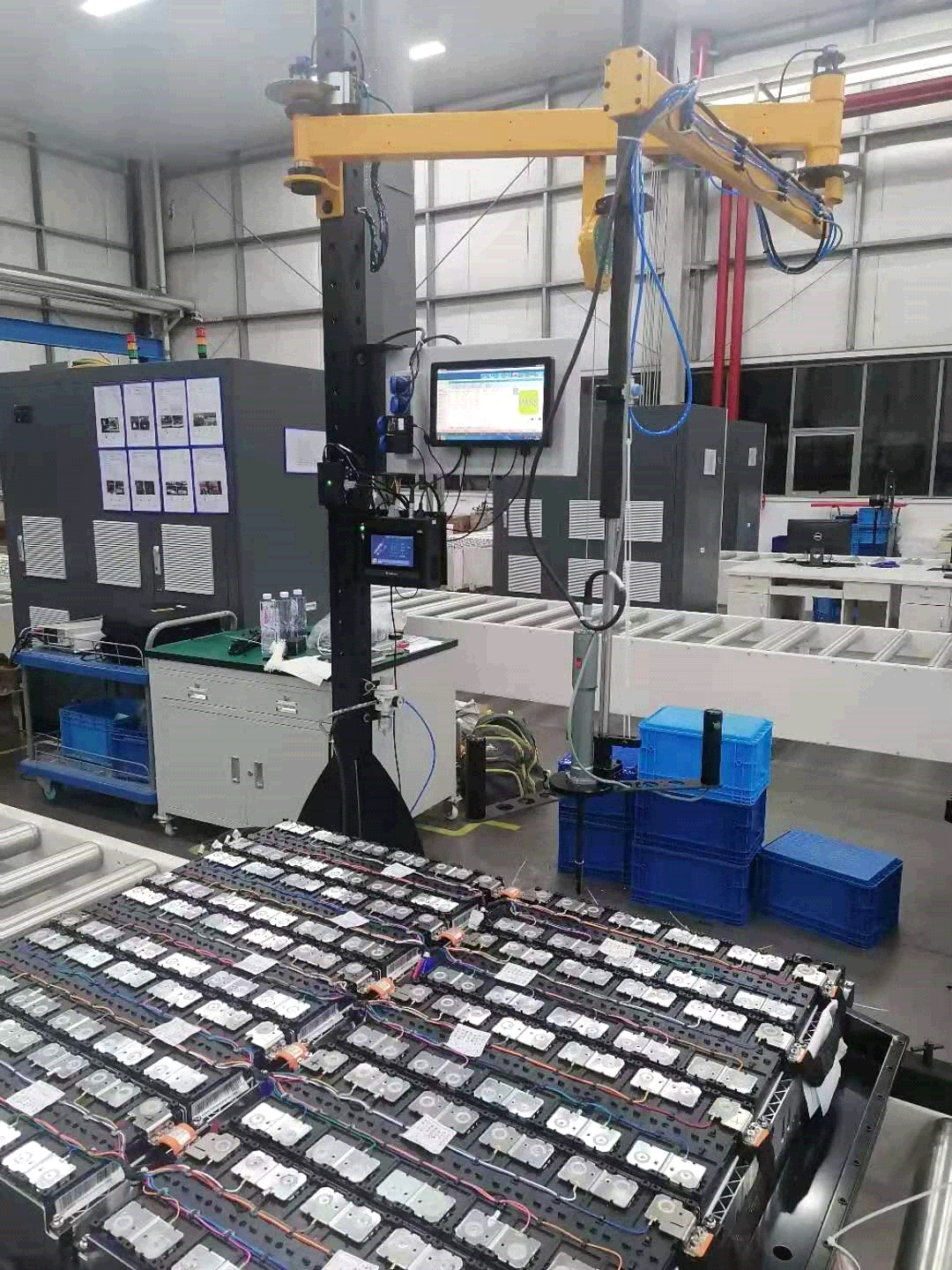

As the core component of electric vehicles, batteries are assembled into battery packs during the packaging stage through laser welding, ultrasonic welding, and pulse welding, or through contact with elastic metal sheets, and then they are assembled mainly using nuts, bolts, zip ties, and harnesses to integrate the battery pack with the electric vehicle, forming a powertrain with other parts. The battery pack has hundreds of screws, and the types and torque of the screws vary, and there must be no under-tightening, missing screws, or incorrect screws, which puts considerable pressure on the assembly line workers.Workbrings considerable pressure.

Automotive battery packs are generally quite large, with lengths and widths exceeding1 meter. Ordinary positioning brackets cannot achieve large-span operations, and the stopping coordinates are random points. Against this background, our company has developedintelligent electric screwdriversand theirintelligent tighteningsystem.This system is designed to address such scenarios, achieving large-span operations for battery packs and a leak-proof and error-proof intelligent tightening system without fixed points.

intelligent electric screwdriversCommonly referred to as intelligent screwdrivers or smart drivers,installationof the intelligent electric screwdriver comes with a tighteningsystem that ensures screws are locked in order, with accurate torque switching for different screws, achieving leak-proof and error-proof functionality.

1. Achieve scanning to adjust the corresponding tightening process parameters to prevent incorrect tightening.

2. Generate a traceable tightening result report for each product code based on the barcode.

3. Achieve coordinate positioning without fixed points, tightening in sequence; prevent missing screws.

4. A 3-meter large arm span achieves no dead angle coverage for oversized products.

5. Accurate coordinate reconstruction and calculation achieve precise positioning of screw holes.

Key words:

Smart electric screwdriver, smart screwdriver, smart driver

Previous article