- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Hotline 19928718048

Why do we need smart electric screwdrivers?

Classification:

Blog

Frequently Asked Questions

Author:

Source:

Release time:

2019-01-23

Visits:

1

When it comes to screwdrivers, everyone is familiar with them. From large factories to small households, we all need screwdrivers at certain times to do what only they can do, which is to tighten screws. Depending on the scenario, due to different specifications and patterns of screws, the required screwdrivers also vary. In the past, it was common to see repair workers carrying a toolbox that contained various specifications of screwdrivers, including both Phillips and flathead types. It seems that the toolboxes carried by repair workers are generally quite heavy.

In recent years, due to the development of the times, people have also demanded convenience and aesthetics from basic tools. Therefore, we can see convenient toolboxes produced by brands like Xiaomi and other foreign brands, where the screwdriver heads can be detached and replaced. Workers only need to carry a complete set of heads to use one screwdriver to tighten many specifications of screws. Additionally, the design is more streamlined and easy to grip, leading some people to enjoy collecting aesthetically pleasing assembly tools, and forums are actively discussing this.

However, this ultimately applies to general assembly situations. A general assembly situation means that the completion of screw tightening is determined by human judgment. Generally, we know that in typical operations, the tighter the screw, the better. If a screw is tightened to the point where it cannot be tightened anymore, it can be considered qualified. However, this requirement, when applied to industrial levels, is a very irresponsible demand. In manufacturing, the assembly of equipment or products must be executed according to certain requirements, which are often determined by the materials used. If one consistently applies excessive force in some situations, it can easily strip softer materials, leading to problems or even scrapping of the product or equipment. Even if there is no stripping, failing to assemble according to specified requirements can also lead to significant quality issues.

Since the concept of Industry 4.0 was introduced, everyone has been discussing smart manufacturing. Assembly, being the most important part of manufacturing, naturally requires intelligence to cooperate. The basic operation of tightening screws, which is almost present in all industrial scenarios, is unique in its repetitiveness and complexity, thus requiring intelligence to simplify its complexity. Therefore, replacing manual labor with appropriate tightening according to the characteristics of products and materials is what smart screwdrivers embody in the current manufacturing environment.

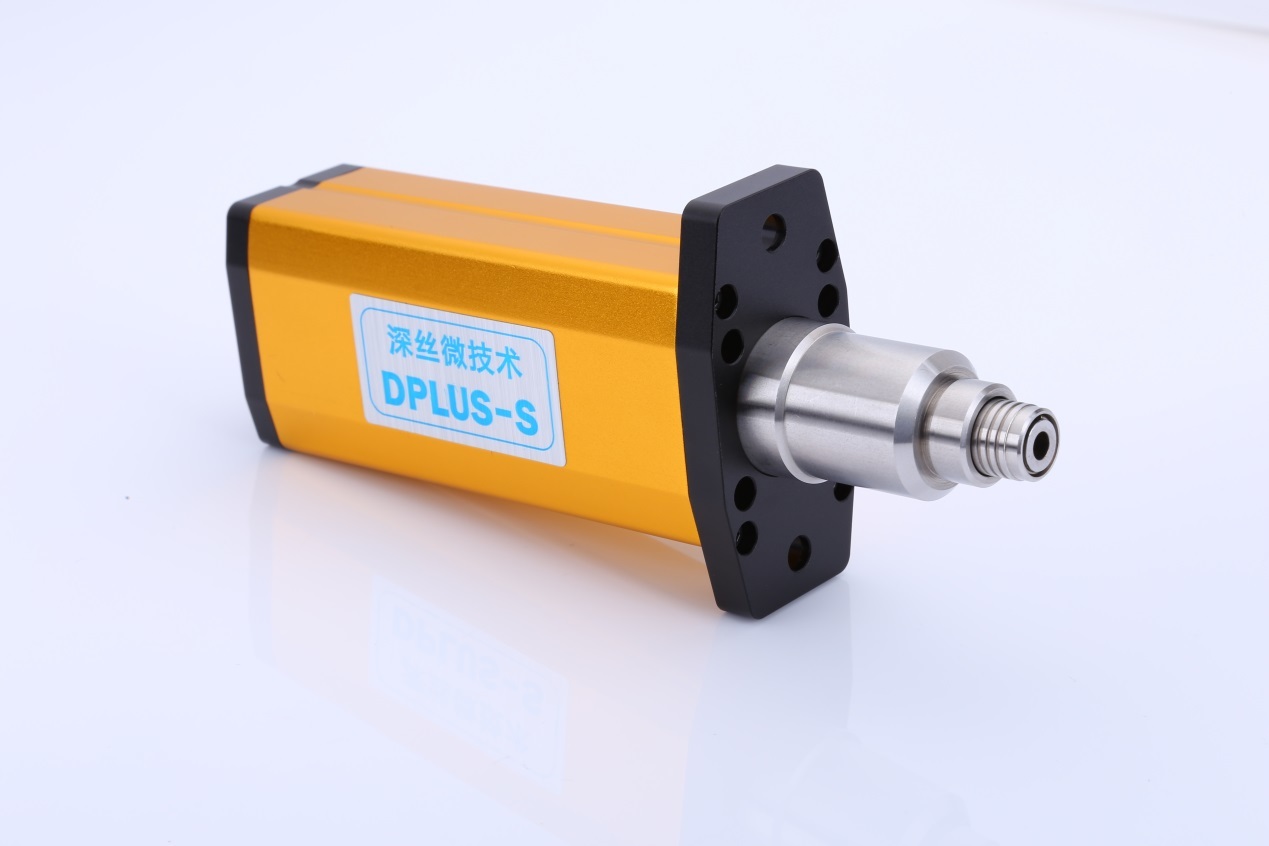

The Sensewee smart electric screwdriver supports 16 types of tasks, allowing it to tighten many different specifications of screws. The real-time monitoring of the torque and angle of the screwdriver head, along with data digitization, ensures that each screw can be tightened appropriately according to requirements. Finally, the tightening data of each screw can be digitized and transmitted to a computer, providing first-hand tightening information to specialized analysts. This not only eliminates tedious inspection tasks but also allows for valuable insights, such as the quality of raw materials, based on the tightening data of different screws. This is a representation of intelligence.

Key words: