- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Hotline 19928718048

The performance of a useful smart electric screwdriver.

Classification:

Industry News

Author:

Sensewee

Source:

Sensewee

Release time:

2023-02-21

Visits:

1

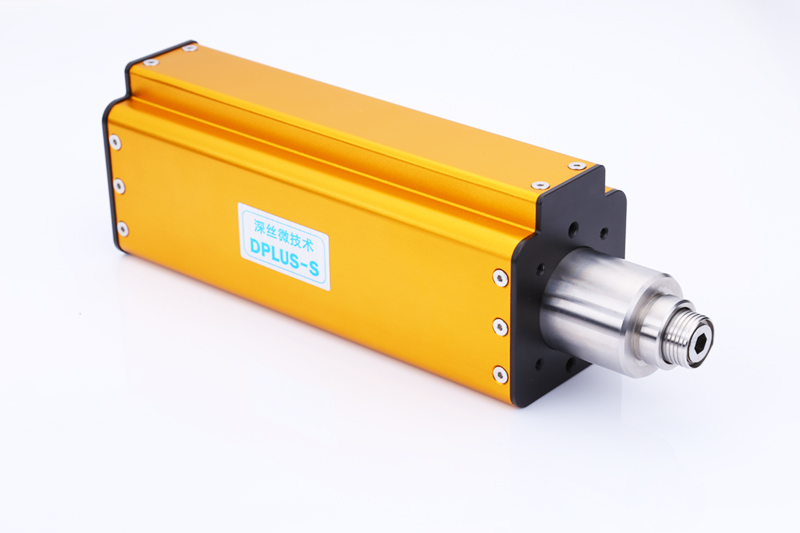

Smart Electric ScrewdriverThe main purpose is for some screw locking scenarios, so its application range is quite broad. It can effectively improve work efficiency and quality, and its practicality is very high. Currently, manufacturers have designed many different types of screwdrivers to meet the usage needs of various industries. Depending on the usage requirements, corresponding products can be purchased. So, what should a good electric screwdriver look like?

1. Intelligence

Since it is a smart electric screwdriver, a basic requirement is that it can achieve sufficient intelligence. In the current era of widespread Internet of Things technology, the manifestation of intelligence mainly includes: advanced control algorithms, customizable and highly flexible working methods, sufficient prompts and records in case of NG situations, and features like communication networking and cloud uploading.

2. High Stability in Screw Locking

In some electronic device industries, there are high requirements for workmanship quality. Even in assembly line production, there will be demands to minimize quality issues and provide consumers with high-quality electronic products. If the completion and stability of some key steps in the production process can be guaranteed, it undoubtedly ensures the workmanship quality of electronic products. Therefore, such smart electric screwdrivers are very suitable for purchase and use in various high-quality requirement industries.

3. No Maintenance Required, Long Service Life

Regardless of the tools used, normal usage will lead to wear and tear, and electric screwdrivers are no exception; this is unavoidable. However, there are now many reliable quality screwdrivers, such as brushless smart electric screwdrivers, which have very low wear and tear, require almost no special maintenance, and are very durable. Their service life can typically reach 3-5 years, saving maintenance expenses and labor costs.

In summary, a good smart electric screwdriver needs to have sufficient intelligence and be able to adjust the tool's work tasks according to usage needs. At the same time, the work tasks must maintain stability to ensure high performance, even if different people use the screwdriver, there will not be significant differences in operational quality. It also needs to be durable.

Key words:

Smart Electric Screwdriver

Previous article