- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Hotline 19928718048

The unsung heroes behind protecting Mobile quality

Classification:

Smartphone Assembly

Author:

Source:

Release time:

2019-01-21

Visits:

1

Recently, a Weibo post shared by Huawei's Yu Chengdong not only went viral among friends but also sparked extensive discussions among netizens about mobile quality. It inevitably reminds people of the various jokes about Nokia's durability from long ago. In recent years, domestic mobile phones, represented by Huawei, have supported half of the domestic mobile phone market. In addition to functionality and technological improvements, the quality of domestic mobile phones has also greatly improved. Shanzhai phones, known for their poor quality, are no longer synonymous with domestic mobile phones.

From the images circulated online, the entire mobile phone is already bent, and the screen has turned into a web of shattered pieces. However, netizens unexpectedly found that its software functions can still run smoothly, indicating that aside from the screen damage, the circuit board remains largely intact and undamaged. While we applaud the resilience of Huawei mobile phones, what kind of magical force allows a mobile phone dropped from a height of 20 floors to remain relatively intact?

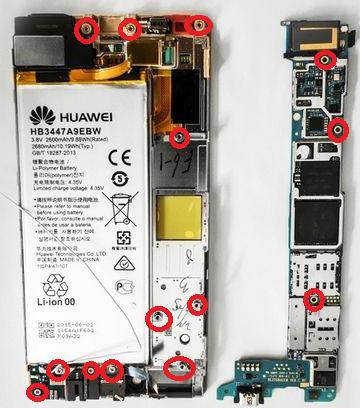

People have differing opinions, so let's peel back the layers of confusion to see the essence. The quality of the mobile phone is excellent, not only due to reasonable structural design and strict material selection but also because of the numerous screws inside the mobile phone providing reasonable protection. The internal PCB and casing of the mobile phone are filled with various small screws. As shown in the image below:

Times are changing, and mobile phones are becoming lighter and lighter. Within the extremely small internal structure of a mobile phone, everything is intricately connected. Don't underestimate these tiny screws; they ensure that there is no significant detachment or misalignment between the internal modules of the mobile phone, thus ensuring hardware integrity. However, locking such small screws is not an easy task; too much torque can strip the screws, while too little torque cannot secure them. Getting these tiny screws tightened properly is indeed a technical job.

The S-type and L-type smart electric screwdrivers launched by Sensewee are intelligent tools specifically designed for tightening such small screws. The smart electric screwdriver has adjustable torque, with precision reaching 5%; it can achieve multi-speed adjustments for a fast-then-slow tightening method; it can set tightening plans according to different processes and sequences; and it allows for real-time switching between various screw tasks, operating smoothly.

To do a good job, one must first sharpen their tools. Since the advent of intelligent tightening tools with precise torque control, the quality of the mobile phone industry has been greatly ensured, with Sensewee providing protection for the precision electronics industry.

Key words: